Creating interesting shapes with LEDs panels are becoming easier and easier. Many panels are adding features that would allow the screen to be mounted and connected at interesting positions, angles and shapes. Taylorleds newly launched Wafer Shine (WS) Series provides endless creativity and maximizes cost-savings with a master-slave panel design.

The Wafer Shine Series is available in four pixel pitches 1.95mm, 2.6mm, 2.97mm and 3.97mm; perfect for any indoor fixed applications. The WS panel consists of 3 pieces; one main panel (master) and two smaller modular (slave) panels. The master panel is 500x500mm in size enclosed with the power box and receiving card giving the slave panels the flexibility to be mounted on any side of the master panel. Each slave panel is 250x250mm in size making these great for modular creativity to fit any spatial needs and aesthetic desires.

Most LED panels need to be mounted and lined up corner to corner, but with WS, it can be mounted at different levels, creating a laddering effect. Slave panels can be used without the master panel by incorporating a power supply and receiving cards into one of the slave panels. A row or column of slave panels can easily be added to a screen to achieve the desired screen size.

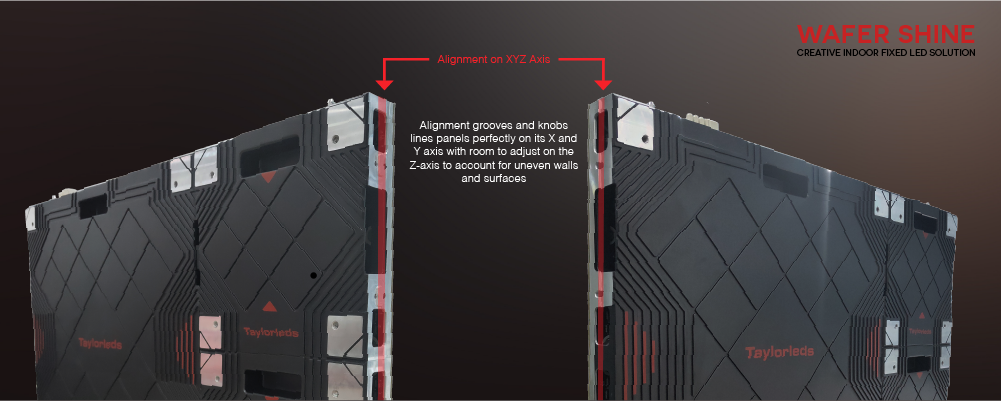

The WS Series light and thin frame makes these panels easy to mount on walls or any surface. Panels connect with each other through integrated wireless connectors, minimizing cables between panels and also reducing cluster inside of panels. All panels have extra ports to connect ribbon cables for creative uses. All sides of the panels have alignment grooves and knobs which lines the panels perfectly on its X and Y axis with room to adjust on the Z axis to account for uneven walls and surface.

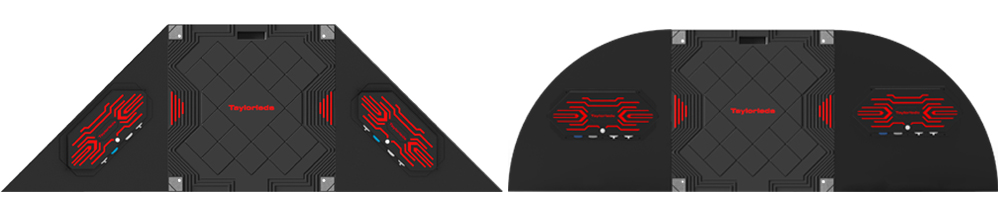

The WS series isn’t complete without creative add-ons accessories. To create easy curves, WS series also has TFAS available; the two-screws system in which one screw is used to secure the curve and the other to tighten the screen together creating a seamless curve. The WS wouldn’t be short on the 45° panels. Special 45° chamfer frames create corners and angled screens at 90° to 150° in 5° increments. With these panels, the seam at the corner is greatly reduced to the thickness of one PCB board. A curved panel to create convex screens. These panels use soft modules which makes it easy to mount on these curved screens, to give a seamless screen. Triangular and circular panels are available; these panels are 500mm in length and can easily attach on any sides of the panels.

Taylorleds main focus is designing products with the end users in mind. The WS Series changes the way screens are mounted and used; opportunities are endless.